Amid the surge of AI innovation ushered in by breakthroughs like ChatGPT, how are Generative AI and Large Language Models shaping real-world business strategies? To answer this, Nordea's Johan Trocmé turned to Hugo Nordell, a seasoned entrepreneur with roots in Silicon Valley's drone and autonomous driving sectors, and a former executive at industry giants like Sandvik and Aker Group. As the founder and CEO of Encube, his latest venture offers a collaborative design engagement platform designed to empower manufacturing firms to overcome R&D hurdles using AI-powered tools. Encube's mission is to streamline the journey from concept to market and cut unnecessary costs for new product development and introduction.

Johan Trocmé (JT): You are comfortable both in the technology and manufacturing industry domains. As a start, would you briefly describe your background?

Hugo Nordell (HN): I come from a diverse academic background that includes physics, mathematics and economics, and I studied in the US, UK and Sweden. I’m very passionate about creating software that has a tangible impact on our physical world. At the beginning of my career, this curiosity led me to Silicon Valley, where I ended up working on autonomous driving before it was the well-known phenomenon it is today. Back then, it was far less glamorous than it is usually portrayed. For me, it mostly meant spending countless hours in overheated backseats of retrofitted cars in parking lots, perfecting the technology.

After that, I launched several startups, including one in the drone space, and held leadership roles such as Head of Product and CTO, focusing on incorporating what we now call "machine learning" into autonomous technology and industrial applications.

I was eventually headhunted to Sandvik, where I built the company's digital transformation for six years, overseeing numerous acquisitions and new software product launches. Before starting Encube, I joined Norwegian industrial group Aker Group as Senior VP of Digitalisation, and repositioned the group’s portfolio companies to better develop, deploy and maintain software and value-added services.

JT: Tell us about the founding of Encube – how did it all start, and what made you do it?

HN: After having experienced the industrial world from both the lens of a startup as well as that of large industrial players, I found that the same set of hardware R&D bottlenecks kept surfacing in both camps. Getting new hardware products out the door to the market is incredibly difficult. Not just in terms of the effort involved – that is largely blood, sweat and tears. It is the way the hardware development process itself runs that is the issue. There is very little automation in place for day-to-day work to help people collaborate better. The software in use isn’t nearly as practical, timesaving and productivity inducing as you’d expect. It’s in the way, more than it is helpful. As a result, incredibly talented engineers waste time on mundane tasks that don’t drive the hardware process forward. This lack of collaborative mechanisms in software tooling makes hardware R&D fraught with human error and causes significant lead times and project cost overruns. The product design that makes it into production is too often not nearly as cost efficient as it could be. Large companies are capable of swallowing these excess costs in the short term, and find productivity in manufacturing over time. But for hardware startups, this fragmented way of working and collaborating is often a death sentence.

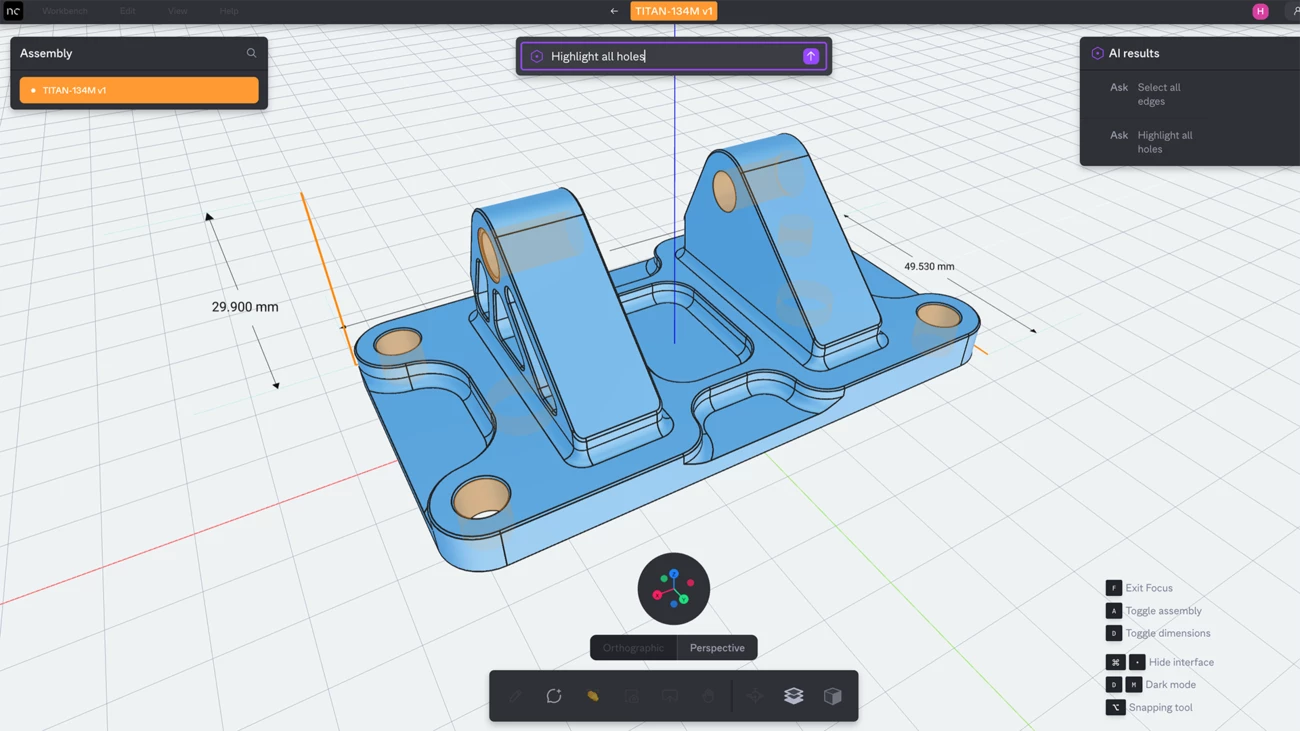

It dawned on me that the manufacturing world is trying to address these hardware design problems from the wrong end of the value chain. Making large capex investments to drive manufacturing automation does little to improve the situation if you’re pushing poorly designed hardware requirements through your shop floor. At worst, it will dig you deeper into the hole you’re trying to get out of. The problems have to be addressed at the root, which is upstream, in the hardware design process itself. And the starting point of that spells better design and requires collaboration between engineering, manufacturing and procurement. Using software that is inherently designed to shift what you as engineers spend your time on day-to-day. As it turns out, generative AI, large language models and traditional robust process automation are great tools to help accomplish this.

We founded Encube on the core premise and philosophy that people ultimately drive business processes. So, any software we build must put people at the centre of the experience, deliberately designed to help them make better, faster and more data-driven decisions. Not to replace the human in the loop, but to fundamentally empower people in hardware engineering to spend their time solving the hard problems that brought them into engineering in the first place. Not to waste their time identifying potential manufacturing issues and cost drivers, but what to do about them.

AI, deployed meaningfully, is exceptionally good at doing repetitive work accurately, over and over. Often with significant time savings as a result. By deploying many finely tuned AI models to solve important but mundane and repetitive tasks in the hardware engineering cycle, Encube can free the hardware team to do what it does best: look at the big picture.

This has been a key learning from the very start for us. Instead of trying to build a single big AI model that should do everything, divide-and-conquer the problem into smaller subsets. Identify the smallest common denominator and tailor an AI model to manage that, and nothing else. One AI for one task. Many AIs to accomplish something overall.

This approach to developing solutions is cost-efficient, fast and makes it much easier to quickly understand if something scales beyond a controlled environment. It reduces technology risk and allows everyone involved to continuously see and experience tangible improvements along the way, rather than have their fingers crossed for the occasional big leap. It also makes it much easier to tie development to tangible and measurable business goals, such as lead time reduction or cost per part. Process governance is only possible with measurable metrics, after all.

In manufacturing, this is commonly known as continuous improvement, and it absolutely scales to AI development and deployment, too. I’m convinced that many industrial organisations will find much more consistent and positive results if they decide to adopt this way of engaging with AI, instead of the boil-the-ocean approach I see many pursue in the fear of missing out.