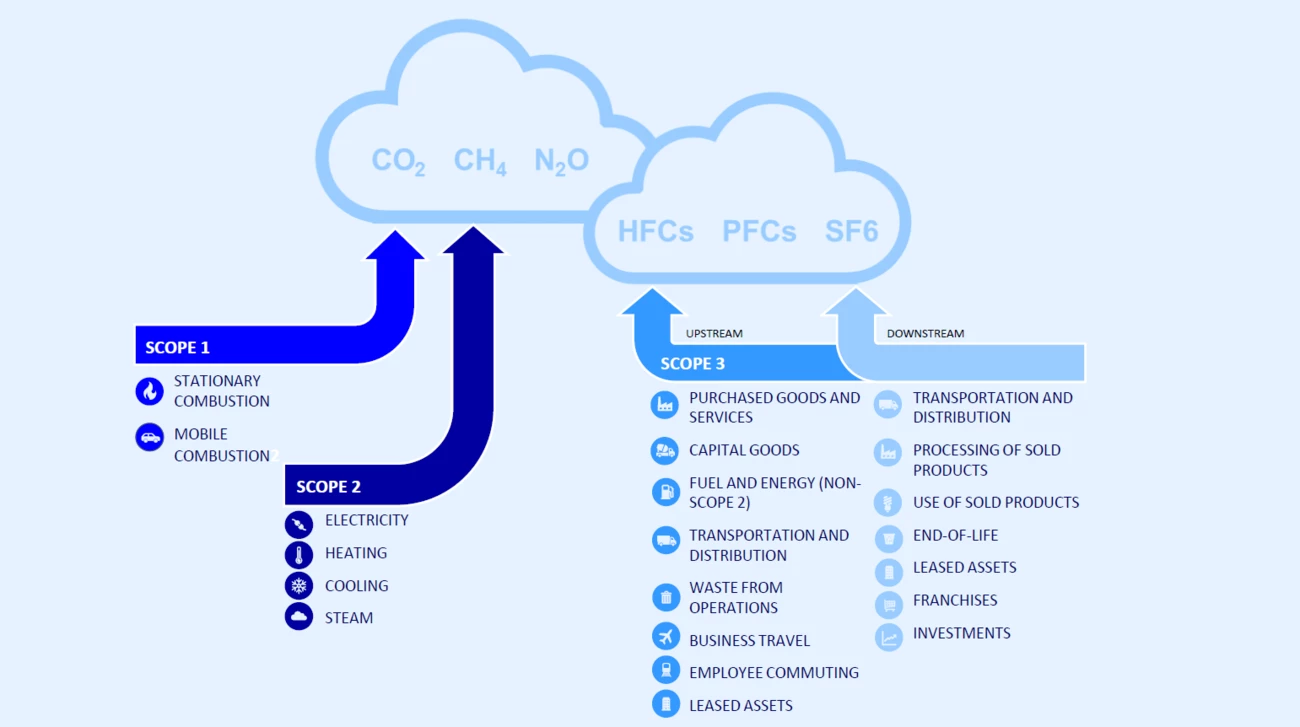

In the first installment of this article series, we discussed the importance and benefits of addressing supply chain emissions, as well as some of the challenges faced as a result of supply chain complexity and data uncertainty. In part 2, we present some methods for how to take ownership of emissions from the value chain, also known as scope 3 or indirect emissions.

Comprehensively addressing issues relating to supply chain emissions can require more than one type of approach. Here we address two broad categories of approach to supply chain decarbonisation: engagement and strategy integration. While engaging directly with companies in the supply chain can improve risk management, devising a broader business strategy to limit supply chain emissions can also be a source of opportunity and innovation for proactive companies.

Although the two approaches can be carried out independently, a combination of both engagement and strategy integration is a prerequisite for the most robust decarbonisation or zero-emissions plans. Instead of conflicting, engagement and strategy integration can be complementary, aiming to limit both the impact of the supply chain and reliance on it.

Approach to engagement

Engaging directly with the supply chain can be an effective method of reducing scope 3 emissions. Depending on the maturity of a company’s supply chain management, this process can be viewed as an expansion of existing risk management measures. As highlighted in the previous article, communicating intent can be an appropriate first step in the process. Follow up and more targeted engagement can range from requesting emissions data to incentivising improvements in performance.

As there can be considerable time lags involved in the process – between initiating requests, gathering and reporting data, and initiating change – it is recommended to initiate engagement as early as possible, even if longer-term internal targets have not yet been set. Supply chain engagement can be a collaborative and ongoing process, so small steps, such as requesting high-level emissions data, can be taken before more intensive requests are made.

An engagement strategy may incorporate the following steps:

- Communicate intent and request baseline data from companies in the supply chain. This can help with mapping supply chain emissions and associated risks.

- Set expectations for improvement. This can address different areas, first targeting improvement in data quality and availability and then in performance.

- Integrate emissions performance standards into procurement requirements.

- Collaborate with supply chain partners. Both through general or sector initiatives and one-on-one. It is this collaboration that will drive lasting change.

- Report and monitor. Reporting on own emissions, as well as supply chain emissions, can benefit the whole ecosystem.

Flexibility should be built in to any supply chain emissions engagement plan in order to accommodate varying levels of influence and control. For example, engagement should account for the level of influence that the engaging company has with the supply chain partner, and the level of control that the supplier has over their own emissions. Effective engagement is a two-way, often iterative, process.